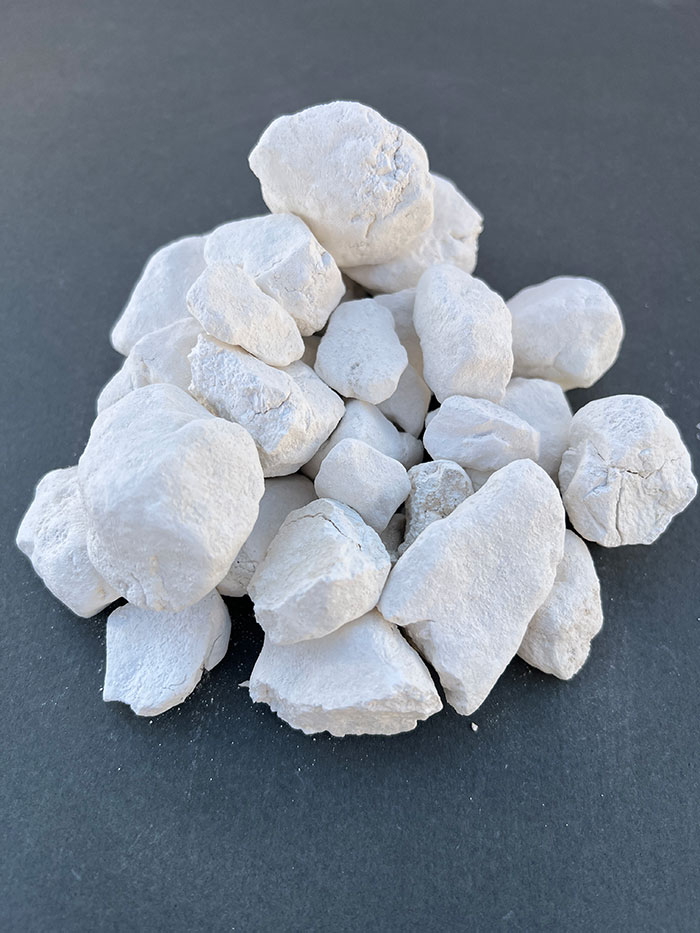

Calcined lime (burnt lime) is produced by calcining limestone (CaCO3). Calcination is the process of removing CO2 from limestone. Heating limestone to approximately 1200°C yields calcium oxide, also known as quicklime (CaO). In domestic production, less than 3 million tons of limestone are used in the metallurgical industry, with about half consumed in steel production.

Calcined lime is a crucial fluxing agent in steelmaking. However, lime used in the steel industry must have the highest possible CaO purity and minimal impurities such as SiO2, sulfur, and phosphorus.

analysis :

Chemical analysis Calcined Lime table

|

Grain Size(mm)

|

Bulk Density (gr/cm3) |

L.O.I |

AL2O3

|

Fe2O3 |

CaO

|

SiO2 |

MgO |

Chemical Analysis(%) Brand |

Product Name |

|

0 - 50 |

0.9 – 1.5 |

1 – 3 |

0.1 – 0.3 |

0.3 – 0.5 |

93 -97 |

0.6 – 1.3 |

0.5 – 1.5 |

AZ.C.L.L (Lime) |

Calcined |

Applications:

- Construction Industry:

- Used in cement production and as a component in lime and gypsum mortars.

- Metallurgy:

- Acts as a flux in steelmaking to remove impurities and is used in non-ferrous metal refining.

- Chemical Industry:

- Serves as a raw material in the production of various chemicals and for pH control in chemical processes.

- Water Treatment:

- Used for water softening and pH adjustment in treatment plants.

- Environmental Applications:

- Used in flue gas desulfurization to reduce sulfur dioxide emissions and in soil stabilization to improve soil properties.

- Agriculture:

- Corrects soil acidity and serves as a calcium supplement in animal feed.

- Food Industry:

- Used in food processing for water treatment and as a clarifying agent.

FA

FA  EN

EN  AR

AR